Process

- Lamination, cutting & sanding

- Coating & finishing

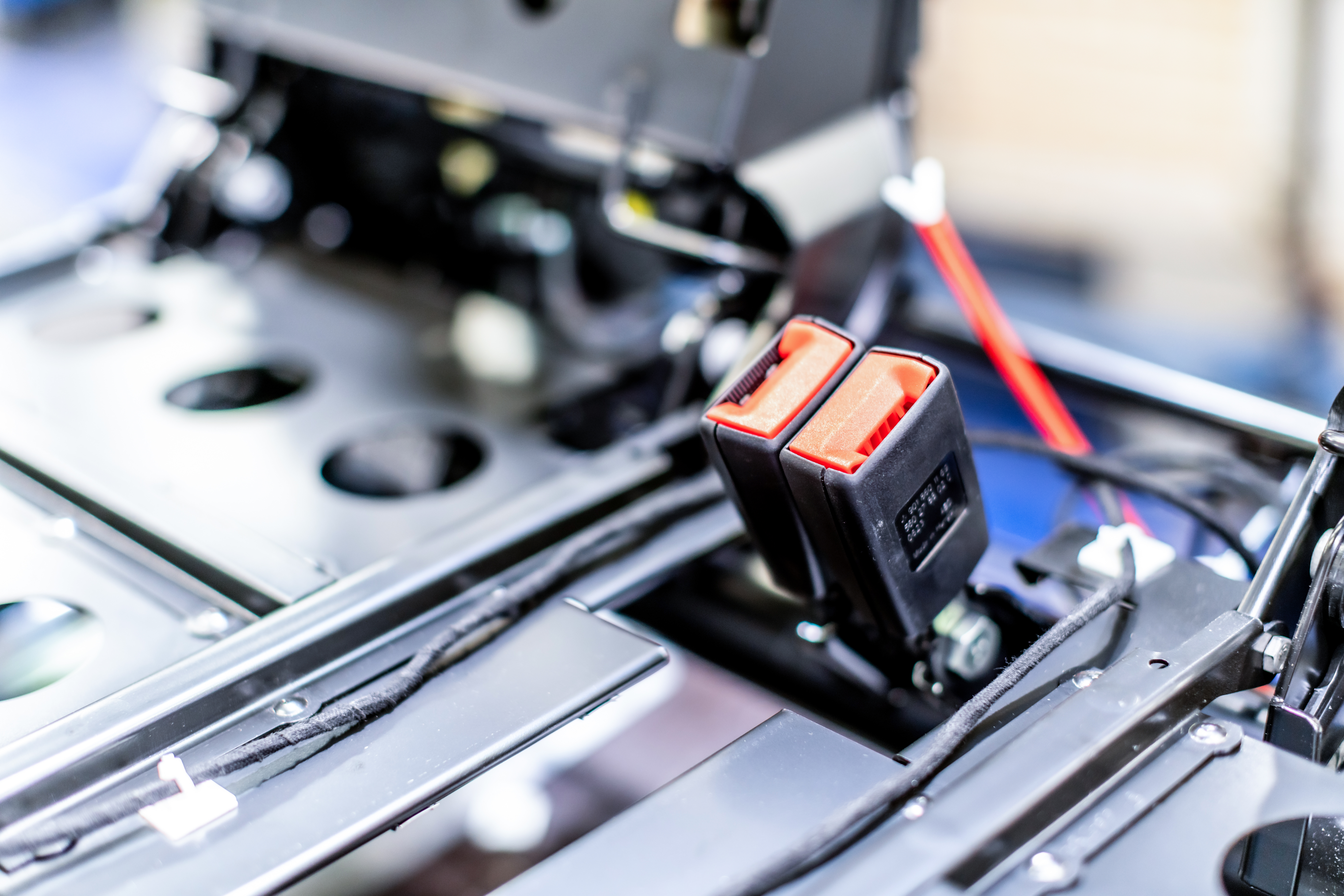

- Pre-assembly

- Internal logistics

- Final assembly inside the motorhome

Roof production

In our modern roof production unit we exploit our decades of experience in the planning and manufacture of glass fibre reinforced roofs and spoilers – both for our vehicles and as supplier to other sites of our group.

Through our multi-disciplinary team of committed industrial engineers, technicians and qualified process engineers in plastics and coating technology, we guarantee the very highest of quality and reliability in terms of product design, process development and production. We also stand out through the versatility of our lamination processes: from traditional hand lay-up and light RTM processing right up to semi-automated RTM production technologies. Our modern and fully automated machining centres for the further processing of individual parts guarantee the highest levels of precision.

Nor do we forget the environment: we coat our roofs and spoilers with water-based paints in colours selected by the OEM customer.